These systems are used by major welding contractors around the world to save time and money while achieving clean shiny welds. Nitrogen argon or helium may be employed for inner protection.

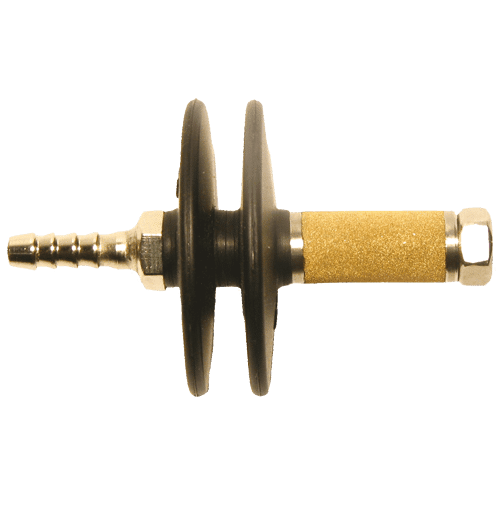

Double Seal Gas Finger Purge System 16 19mm Welding Welder

Double Seal Gas Finger Purge System 16 19mm Welding Welder

Valves will prevent unwanted and undesirable changes from causing weld failure due to lost purge as a result of dam burst.

Purge system welding. Unwanted connections can be left closed with the blanking plugs provided. Manufactured in sizes 6 to 88 150 to 2235 mm HotPurge. Advertentie Water Soluble Purge Dams Water soluble socket weld spacers.

Advertentie Leading Pipe Weld Purging Equipment. 14-11-2017 Welding Methods. I-Purge creates an impermeable seal to consume the least amount of purge gas during pipe purging and welding saving time and money while achieving consistent high-quality welds.

Before welding of stainless steel pipes it is recommended to purge the pipe. Advertentie Water Soluble Purge Dams Water soluble socket weld spacers. The weld purge process Once the quality of the gas in the dammed volume has reached the required level gas Fow can be reduced to about 5 lmin for the welding operation.

However nitrogen cannot be used in the case of weld materials having a. The revolutionary patent-pending I-Purge Modular Inflatable Bladder System is the most innovative and versatile pipe purging system available. Welding purge system Purge Flex manufactured by WELD-TECH is a double seal purging system that works in the ranges from 25mm to 320mm.

These purging systems also have the advantage of additional gas inlets and exhausts to accommodate high flow rates of purging and exhaust gases. Particularly valuable for the welding of high specification stainless steel titanium and other reactive alloys. When welding the more sensitive alloys based on titanium zirconium and other reactive metals the residual oxygen levels need to be in the region of 001 10 ppm or less.

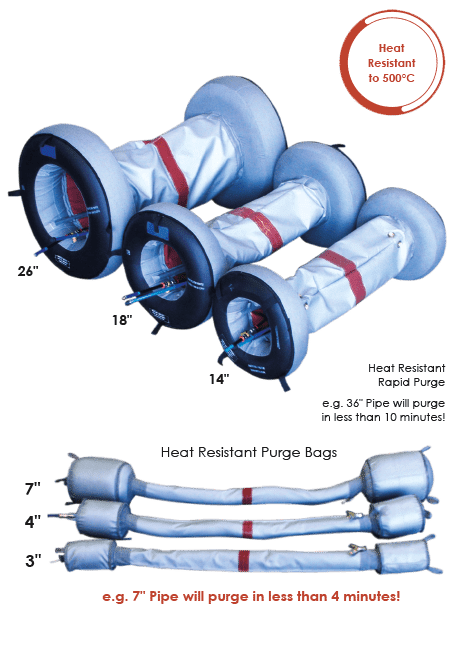

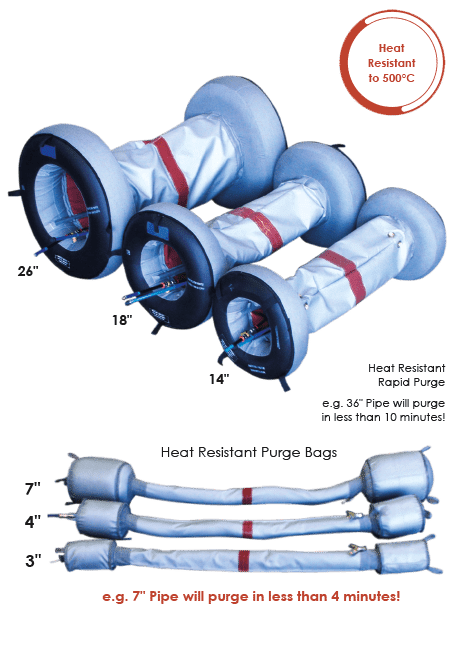

Purging Gases The process of weld purging is typically done in GTAW and TIG welding. The welding literature 134 recommends that the back purge flow rates be low barely detectable at the gas exit port and makes no reference to the welding torch flow rates at all. The Purge Bag Systems in the range manufactured by PPM are designed around the principle of using 2 dams to create a seal either side of the weld just far enough away from the weld not to be effected by heat but close enough to the joint to provide the fastest weld purge time.

Weld-purging-equipment Inflatable Purge Systems are the fastest most effective pipe purging systems available. Turn the BLUE gas hose on to inflate the bladders and purge the weld zone. The purity of the gas shall be certified by the manufacturer.

Systems can be used repeatedly for weld purging and can keep the oxygen levels below 100 parts per million ppm throughout the welding cycle. Inflatable Tube Pipe and Pipeline Weld Purging Systems are at risk of overinflating during the weld purging process due to unwanted manipulation of gas pressure and flow settings. In this work it was determined that the selection of shielding gas flow rates for both the back purge and the welding torch are critical in the making of sound root-pass welds.

Argon is the most commonly uses purging gas but helium can also be used. Weld purging is the act of removing from the vicinity of the joint oxygen water vapour and any other gases or vapours that might be harmful to a welding joint as it is being welded and immediately after welding. Position the purge unit in the pipe using the luminescent indicator as a guide to center the system across the root gap 7.

Argon gas used in GTA welding for shielding purposes shall be 99995 pure. These dams are connected by an armoured spinal tube. Nitrogen however should not be used on stainless steel.

PurgElite Purging System product line has been an industry leader in pipe and tube weld purging technology for over 20 years and pioneered the tandem inflatable purge dam concept which has become one of the most widely used purge methods for welding stainless steel duplex titanium and other pipe and tube joints. Purge Flex is easy to pull through pipes and bends without tilting. Advertentie Leading Pipe Weld Purging Equipment.

New Superalloys Need Careful Purging During Welding Stainless Steel World

New Superalloys Need Careful Purging During Welding Stainless Steel World

Argweld Quick Purge Pipe Purging Systems Forgeweld Ltd

Argweld Quick Purge Pipe Purging Systems Forgeweld Ltd

Argweld Quickpurge Inflatable Tube Pipe And Pipeline Weld Purging Systems Youtube

Argweld Quickpurge Inflatable Tube Pipe And Pipeline Weld Purging Systems Youtube

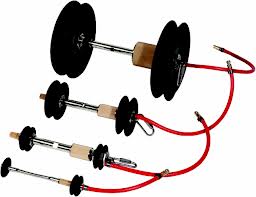

Tag Double Seal Purge System 150 165mm Welding Welder

Tag Double Seal Purge System 150 165mm Welding Welder

Purging Equipment Systems For Welding Intercon

Purging Equipment Systems For Welding Intercon

Heat Resistant Rapid Purge System 42 1023 1048mm Welding Welder

Heat Resistant Rapid Purge System 42 1023 1048mm Welding Welder

Quick Purge Inflatable Pipe Purging Systems For 8 42 Quick Purge Inflatable Pipe Purging For 8 42 Arc Zone Pge Psq008 042 797 30 Arc Zone Com Welding Accessories Store

Quick Purge Inflatable Pipe Purging Systems For 8 42 Quick Purge Inflatable Pipe Purging For 8 42 Arc Zone Pge Psq008 042 797 30 Arc Zone Com Welding Accessories Store

Inflatable Pipe Purging Systems For Zero Colour Welds Engineer Live

Inflatable Pipe Purging Systems For Zero Colour Welds Engineer Live

Argweld Purgelite Purging System Inflatable Tube And Pipe Welding

Purgelite Inflatable Pipe Purging System Inexpensive And Effective

Purgelite Inflatable Pipe Purging System Inexpensive And Effective

Flex Purge System Orbital Tools Nz

Flex Purge System Orbital Tools Nz

Weld Purge Dams For Dished Ends And Short Pipes

Weld Purge Dams For Dished Ends And Short Pipes

Http Www Stainless Steel World Net Pdf Weld Purging For Tubes And Pipes Pdf

Why Should You Use Inert Gas Purging When Welding Stainless Steel Titanium And Nickel Alloys

Why Should You Use Inert Gas Purging When Welding Stainless Steel Titanium And Nickel Alloys

Huntingdon Fusion Techniques Hft Pacific Automated Welding Solutions Pipe Weld Purging Systems Weld Purge Monitors Fabrications